NW Natural, a natural gas distribution utility based in Oregon, is working with Seattle-based EnerG2 to develop adsorbed natural gas technologies aimed at improving on-board compressed natural gas (CNG) storage for natural gas vehicles.

‘We believe the adsorbent technology that we're developing with EnerG2 will make natural gas fleets an even more attractive choice for business owners,’ says Chris Galati, NW Natural's CNG program manager. ‘We hope to partner with other companies and agencies as our research and development project progresses.’

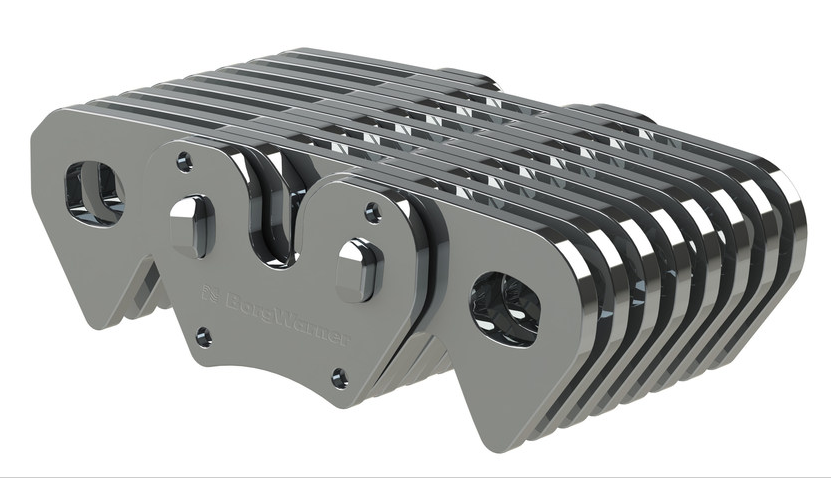

EnerG2 first announced its carbon adsorbent material in December 2013. It is designed to enable natural gas to be stored at 500-800 psi – in a volume similar to what's traditionally stored at 3,000-3,600 psi. The adsorbent material packs inside an existing CNG tank and increases the energy density of natural gas at a given pressure, allowing a vehicle to travel longer distances.

EnerG2 says it has already produced its material, which is compatible with all tank geometries and systems, at scale.

‘Our carbon adsorbent material for natural gas enables tremendous design efficiency and no wasted space, because a low-pressure tank can be shaped more like a traditional gasoline tank to fit in a space onboard a vehicle that's about half the size of a high-pressure cylinder,’ says Dr. Aaron Feaver, chief technology officer and co-founder of EnerG2.

NW Natural and EnerG2 say they expect to complete a series of bench tests and vehicle road tests in the second quarter.