Efficient Drivetrains Inc. (EDI), a provider of advanced high-efficiency zero-emissions hybrid and electric drivetrain solutions, has expanded its solutions portfolio to include its EDI PowerDrive electrification kit and developer support program for vehicle manufacturers moving to create a plug-in hybrid electric vehicle (PHEV) offering.

According to EDI, the first-of-its-kind OEM vehicle developers kit and support program enables manufacturers to rapidly create PHEV and EV vehicle solutions that meet current industry regulations.

EDI says that its PowerDrive kit includes a high-efficiency drivetrain (EDI PowerDrive), vehicle control and telematics software (EDI PowerSuite), and the training and support infrastructure to enable OEMs to drive quicker time to market in offering PHEVs and EVs. OEMs can further customize their vehicle solutions with EDI’s Electric Power Export (Power2ETM) option – the capability to export a range of power directly from the vehicle for use in disaster recovery, job-site maintenance, tool operation and other applications.

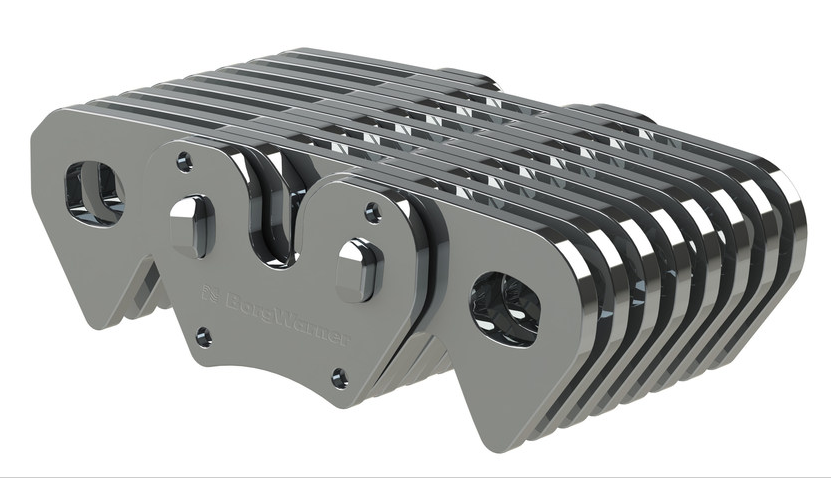

EDI asserts that its PowerDrive system is less complex, more efficient and lighter than any offering in the industry. The distinctive, inline form factor allows the drivetrain to integrate into any light-, medium- or heavy-duty vehicle design.

Specifically, the company claims the four-mode system automatically adapts its functions so it can operate as a pure EV for trips around the neighborhood, as a Series Hybrid, which is optimal for stop-and-go city traffic conditions, or as an efficient Parallel Hybrid, which is ideal for the highway. It also features an EV+ mode for hill climbing and added acceleration.

“Moving into mass production of our drivetrain solutions is the next phase of EDI’s business strategy,” says Joerg Ferchau, CEO of Efficient Drivetrains. “As OEMs struggle to build solutions quick enough to comply with regulations, EDI’s drivetrain and control software solutions are ideally suited to help them comply in the shortest timeframe possible.”