The U.S. Department of Energy (DOE) has announced up to $14 million in funding for the advancement of hydrogen fuel technologies, including advanced high-temperature water splitting, advanced compression and thermal insulation technologies.

According to the DOE, these projects will accelerate American innovation in hydrogen and fuel cell technologies by supporting research and development and domestic manufacturing.

The DOE’s current goal is to reduce the cost of producing and delivering hydrogen to less than $4 per gallon of gas equivalent (gge) by 2020 and $7/gge for early markets.

To combat a limited supplier base, the DOE is also announcing the launch of HFCNexus, an online tool for hydrogen and fuel cell technologies, developed through a current DOE-funded project by Virginia Clean Cities at James Madison University. A business-to-business website that connects fuel cell and hydrogen technology developers with potential suppliers, HFCNexus will be a resource when it comes to necessary equipment, such as hoses, nozzles and meters, according to the department.

The projects selected under this funding opportunity are as follows:

High-Temperature Water Splitting

Salt Lake City-based Ceramatec Inc. – Improve the performance of durable materials for high-temperature water splitting stack technology through the development of a novel cell architecture that introduces macro-features to provide mechanical support of a thin electrolyte and micro-features of the electrodes to lower polarization losses.

Danbury, Conn.-based Fuel Cell Energy Inc. – Demonstrate the potential of solid oxide electrolysis cell systems to produce hydrogen at a cost of $2 per kilogram.

Newton, Mass.-based Giner Inc. – Develop high-temperature alkaline water electrolyzers with improved electrical efficiency at a reduced cost.

Advanced Compression

Giner Inc. – Demonstrate a cost-effective method for compressing hydrogen while eliminating the need for mechanical compressors, which can have significant reliability issues.

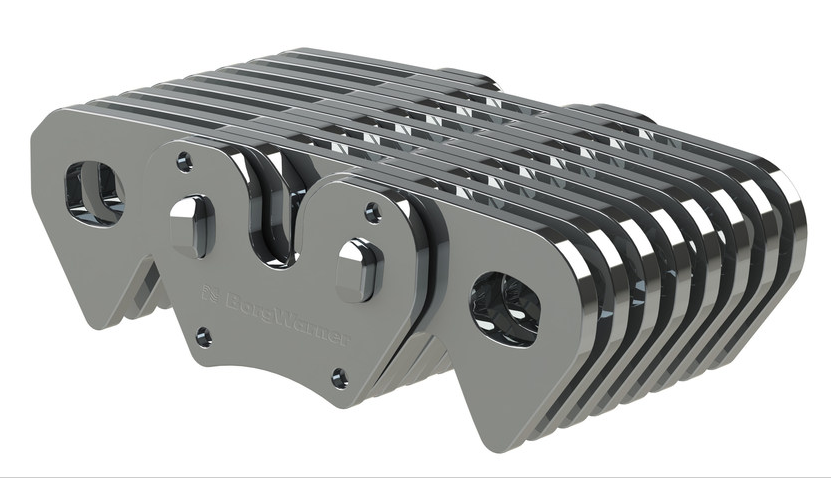

Aiken, S.C.-based Greenway Energy LLC – Combines two novel technologies, Electrochemical Hydrogen Compression and Metal Hydride Compression, into a new hybrid solid state hydrogen compressor in order to overcome the reliability issues of mechanical compression and the efficiency challenges of solid state compression technologies.

Livermore, Calif.-based Sandia National Laboratories – Investigate and demonstrate a laboratory-scale, two-stage metal hydride-based hydrogen gas compressor.

Thermal Insulation

Reston, Va.-based Vencore Services and Solutions – Apply integrated cryogenic tank approaches and novel technologies developed by NASA’s Cryogenics Test Laboratory to build an integrated subscale insulation system prototype demonstrating the heat leak targets applicable to cryogenic hydrogen storage tanks for commercially produced fuel cell-powered automobiles.