The National Renewable Energy Laboratory (NREL) and clean hydrogen company Electric Hydrogen have signed an agreement to develop high-performance electrolyzer components, helping to scale clean hydrogen and invent new opportunities for decarbonization.

The three-year, $3.6 million collaboration will diagnose sources of degradation in commercial electrolysis cells and will validate advanced designs that use higher stack currents.

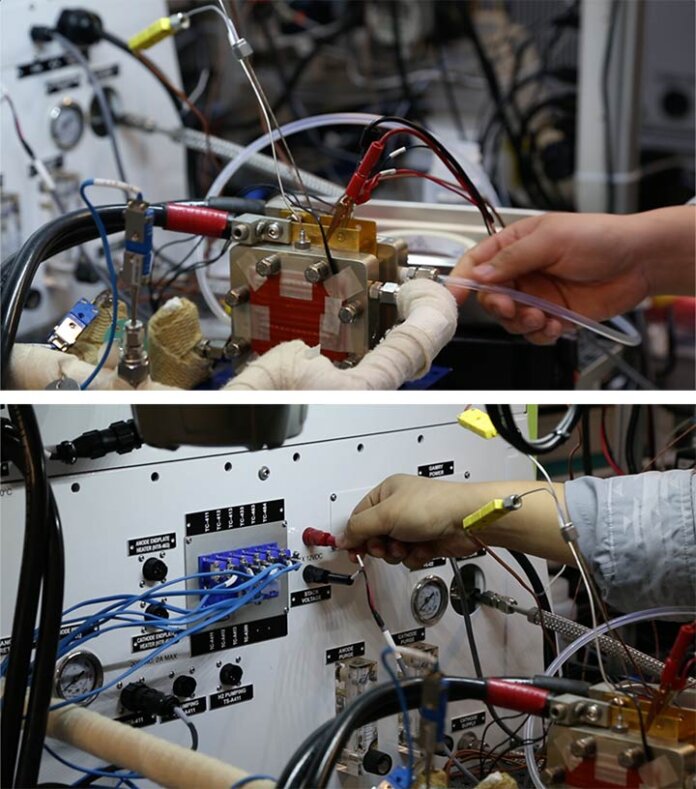

“Electric Hydrogen is engineering a high-performance product for water electrolysis – something that could scale up to significant commercial applications,” says Guido Bender, NREL’s principal investigator on the project. “NREL has pretty unique hardware for testing electrolyzer stacks; this will allow us to characterize efficiency, durability and performance across a range of operating conditions.”

Several of the NREL and Electric Hydrogen team members were also behind a long-lasting NREL-First Solar collaboration, which eventually commercialized cadmium telluride solar photovoltaics. The Electric Hydrogen collaboration hopes to repeat that progress by once again pushing the boundaries of upcoming technology, this time for renewable hydrogen, an energy resource that has the potential to decarbonize the highest polluting sectors.

“Our goal is to build industrial-scale electrolysis so that carbon-heavy industries can adapt,” comments David Eaglesham, co-founder and chief technology officer at Electric Hydrogen. “NREL has a history of helping next-up technologies scale to larger markets, and we are confident that this collaboration will achieve similar breakthroughs for renewable hydrogen.”

The analogy to solar energy’s rise runs deep: Like solar two decades ago, clean hydrogen is currently in profitability limbo, held back by the high capital costs of electrolyzers. However, the U.S. Department of Energy (DOE) hopes to change that with its Energy Earthshot for hydrogen, or “Hydrogen Shot” as it is commonly referred to – an initiative to reduce clean hydrogen costs by 80% to $1 per $1 kilogram in 1 decade. The Electric Hydrogen partnership plays into this strategy by addressing components where costs could be reduced.

“This partnership really creates value in multiple directions,” Bender continues. “While Electric Hydrogen develops its product, we develop our research capabilities to be more sensitive to device degradation, and, as a result, the entire renewable industry benefits as we achieve new benchmarks in cost and performance.”

This project builds on more than a decade of research and capability investment at NREL by U.S. Department of Energy’s (DOE) Hydrogen and Fuel Cell Technologies Office and supports DOE’s H2@Scale vision for clean hydrogen across multiple applications and economic sectors. It will complement ongoing work through two NREL-led, multi-lab consortia: Hydrogen from Next-generation Electrolysis of Water (H2NEW), focused on materials and component integration, manufacturing and scale-up to help support large industry deployment of durable, efficient and low-cost electrolyzers as well as HydroGEN, focused on accelerating development of less mature water-splitting materials and technologies to complement the work of H2NEW.

For the Electric Hydrogen project, the researchers will specifically look at proton-exchange membrane electrolysis and will study the methods of managing heat and degradation with high current densities. The team members aim to integrate and optimize multiple specially engineered layers, shrinking the system size and costs while designing for a future large commercial-scale stack.