Daimler Truck AG technicians at the company’s Stuttgart, Germany, site are developing new fuel cell production facilities that will be used as the technological template for subsequent series production.

Daimler Truck AG is consistently driving forward series production of fuel cells with Daimler Truck Fuel Cell GmbH & Co. KG. In the past 10 years, Daimler technicians have built up extensive knowledge in this field and have developed production methods and processes. In close cooperation with their colleagues in Vancouver, Canada, and with the ongoing fuel cell development activities, the Stuttgart-based experts are now transferring that experience to the direct preliminary stage of future series production.

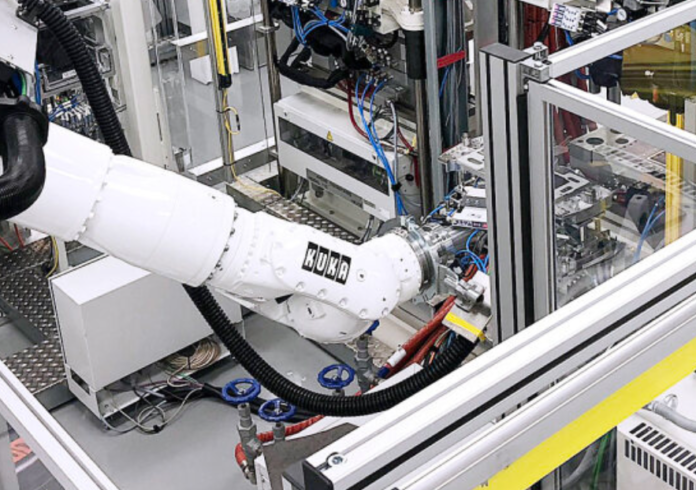

Investments are being made in new facilities covering every single process stage of fuel cell production: from membrane coating and stack manufacturing to the production of fuel cell units.

“We are pursuing the vision of the CO2-neutral transportation of the future. The hydrogen-based fuel cell is a key technology of strategic importance in this context,” says Martin Daum, chairman of the board of management at Daimler Truck AG.

“We are now consistently following the path towards the series production of fuel cells and are thus doing absolutely pioneering work – and this goes beyond the automotive industry. We will invest a very substantial sum in the coming years to achieve this,” he adds.

Conventional industrial production processes cannot be directly transferred to the highly complex and highly sensitive fuel cell stacks. For example, the processing of numerous delicate components takes place in the micrometer range (1 micrometer = 1 millionth of a meter). Even the smallest contamination could impair the functionality of the fuel cells, which is why a clean room with filtered air is being set up for some of the work in the planned pre-series production.

Optimizing the ambient air in production is also especially important since even slight fluctuations in temperature and humidity can lead to significant material changes. This would make further work in subsequent processes considerably more difficult. However, the greatest challenge for Daimler technicians is to achieve short production cycles, which is essential for cost-effective production. For this reason, the experts in the production of fuel cell stacks sometimes rely on technologies from the packaging industry, which are generally not used in conventional engine production.

In April this year, Daimler Truck AG concluded a preliminary, non-binding agreement with the Volvo Group to establish a new joint venture for the development and marketing of fuel cell systems to be used in heavy-duty commercial vehicles and other applications. The companies plan to offer heavy-duty fuel cell commercial vehicles for demanding and heavy-duty long-distance haulage from series production in the second half of this decade.

Rolls-Royce’s Power Systems division plans to use the fuel cell systems for the emergency power generators of the MTU product and solution brand it develops and sells for data centers. A comprehensive cooperation agreement is to be drawn up and signed by the end of the year.