Atlis Motor Vehicles, a start-up EV company developing electric work trucks, batteries and motors, has signed a collaborative agreement with ArcelorMittal, an automotive steels producer, to help speed its product development. Under the agreement, Atlis will use ArcelorMittal’s steel materials knowledge and S-in motion solutions to accelerate its vehicle design.

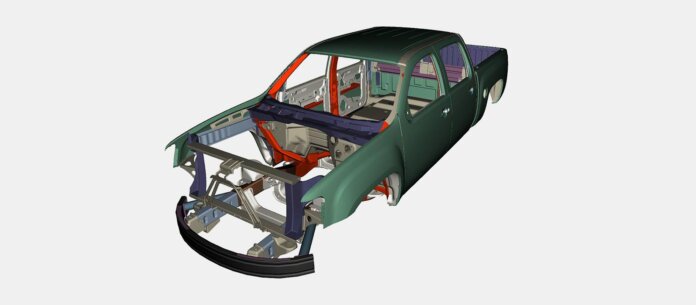

Atlis will use ArcelorMittal’s S-in motion pickup truck model, as well as cab and box designs to help guide the design of its XT, a purpose-built, fully electric pickup truck designed to support individuals and fleet owners who work in agriculture, service, utility and construction industries.

S-in motion is a set of lightweight steel solutions developed by ArcelorMittal for automakers who wish to create lighter, safer, and more environmentally friendly vehicles. Atlis will use ArcelorMittal’s body in white CAD engineering information to reduce weight and cost, while increasing the range of its XT.

The Atlis XP skateboard platform is the base for the 500-mile range electric Atlis XT pickup. A standard XP platform consists of two identical modular drive systems located in the front and rear of the vehicle, four traction motors, independent suspension, drive-by-wire technology and an Atlis battery pack. The modular system is designed to be plug-and-play, from a pickup to a box truck to a flatbed and will enable the vehicle to be serviceable even on the side of the road.

“Our collaboration provides Atlis with designs that have been engineered and virtually homologated for vehicle crash and typical industry structural performance requirements and enable us to speed up product development,” says Mark Hanchett, CEO of Atlis Motor Vehicles. “This is the latest example of how we source key technology and materials from strategic suppliers to meet the demanding performance characteristics needed in emissions-free electric work trucks.”

“This agreement is part of our larger commitment to the path to net zero and our innovation in steel solutions will now help with the transition to a BEV fleet,” adds Dr. Greg Ludkovsky, ArcelorMittal’s vice president of global research and development. “By working together through our industry leading co-engineering efforts, our S-in motion solutions continue to evolve as practical implementable ideas that can provide the safest solution at the lowest cost for the rapidly transforming automotive industry. The agreement with Atlis pushes this further with an automaker using our S-in motion design as the starting point for their BEV truck design.”

The XT pickup will target towing of 17,000 lbs. with a hitch and a max tow rating of 35,000 (GCWR) pounds with fifth wheel and gooseneck. XT configurations include service body upfits; 2 door or 4 door; 6.5-foot and 8-foot beds with dual rear wheel option; and towing capabilities of 10,000 lbs., 14,000 lbs. and 17,000 lbs. XT drivers will be able to choose from a 300, 400 or 500-mile battery pack that ranges from 125 kWh up to 250 kWh capacity and will fully charge in just 15 minutes using a 1.5 MW charging station.