The proper routing and installation of compressed natural gas (CNG) fuel lines is one of the most important factors to consider when performing aftermarket CNG vehicle conversions.

The proper routing and installation of compressed natural gas (CNG) fuel lines is one of the most important factors to consider when performing aftermarket CNG vehicle conversions.

If the fuel lines (both high pressure and low pressure) are not properly packaged on the converted vehicle, premature loosening, corrosion or impact damage to the fuel lines could occur during vehicle operation. This premature damage could cause customer dissatisfaction due to vehicle drivability concerns or, in more severe cases, could cause fuel leaks.

This article will first offer the suggestion to meticulously study the vehicle platforms intended to be converted to CNG prior to starting the conversions, and will then offer a few general considerations for fuel-line routing commonly used by automotive OEMs. The best formula for success in this endeavor is to study the vehicles to be converted and to understand the reasoning used by the OEMs to design their fuel-line routings.

Due to the complexity of this topic and the large number of vehicle platforms currently being converted, this article is not intended to provide any specific fuel-line routing guidance. This article can only share general information about the topic. Each individual converter is responsible to ensure that conversions meet all applicable federal and state regulations.

Study the system

Probably the most important preparatory action the aftermarket vehicle converter can take to facilitate proper routing of the fuel lines is to begin with an in-depth study of the gasoline or diesel fuel systems on the vehicles they plan to convert. This action should be taken for each unique vehicle platform or platform variation that is to be converted, and also should be taken before any actual conversions are initiated. Converters should study the vehicles exactly as they are received from the OEM in order to formulate a plan for the fuel-line routing of their converted vehicles.

The vehicle OEM puts forth a great deal of thought and effort in deciding how to route the gasoline or diesel fuel lines, and this work is verified by extensive laboratory and vehicle testing. This includes fuel system integrity crash testing (FMVSS 301). With this fact in mind, the aftermarket converter should seek to copy and replicate the OEM fuel-line routing as closely as possible.

A few specific items to look for when analyzing OEM vehicle fuel-line routings include the following:

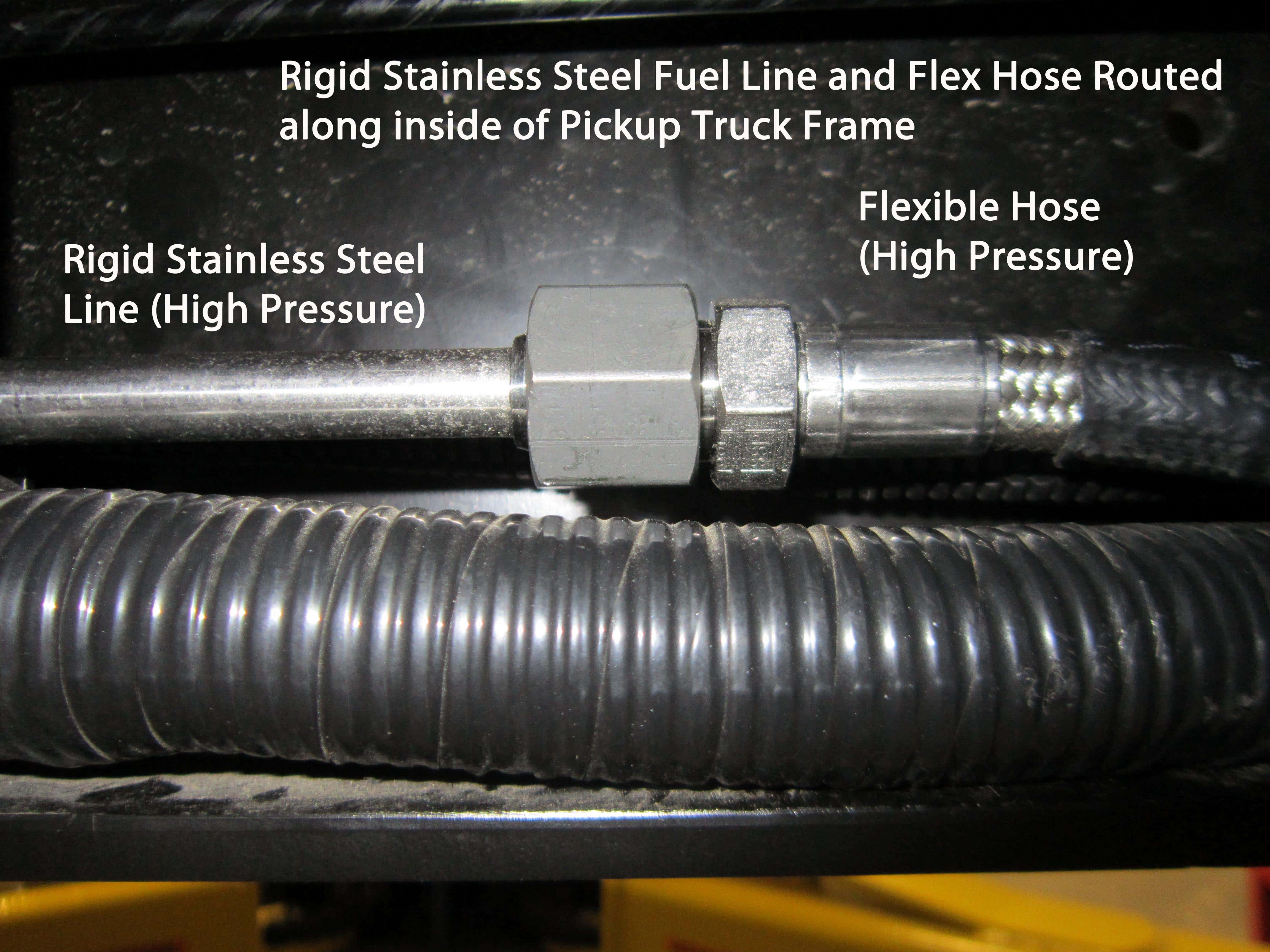

Pay close attention to where the OEM uses flexible hoses versus rigid tubing. Flexible hoses are generally used sparingly on OEM vehicles due to cost and permeation issues. They will typically be found only in areas where compliance is needed either for movement during a crash event or for allowing relative motion of moving components (e.g., suspension, intermediate steering shaft or engine/transmission). A converter will likely want to use flexible hose for the CNG fuel lines in the same areas as does the OEM, in order to take advantage of the design work and testing previously done by the OEM.

Study the OEM's methodology for fuel line attachment to the vehicle, and measure the spacing between attachments.

Study the OEM's methodology in making the fuel-line routing ‘jump’ from the vehicle underbody to the engine compartment so it, too, can be replicated. Consider the full range of engine roll motion when studying this aspect of the routing.

Note the locations of the following components and caution points:

- Heat sources, such as the exhaust and catalytic converter;

- Moving suspension components. Do not forget that the suspension will have a travel envelope to keep clear of when routing the CNG fuel lines.

- Intermediate steering shaft. Be aware that this shaft not only rotates, but also has lateral, vertical and longitudinal compliance to accommodate relative motion with respect to other components.

- Sharp edges or protruding objects that could damage the lines if they come in contact with the CNG fuel lines.

Converters will want to route the CNG lines away from these areas and allow for the travel envelopes of the suspension and steering shaft.

A few important considerations

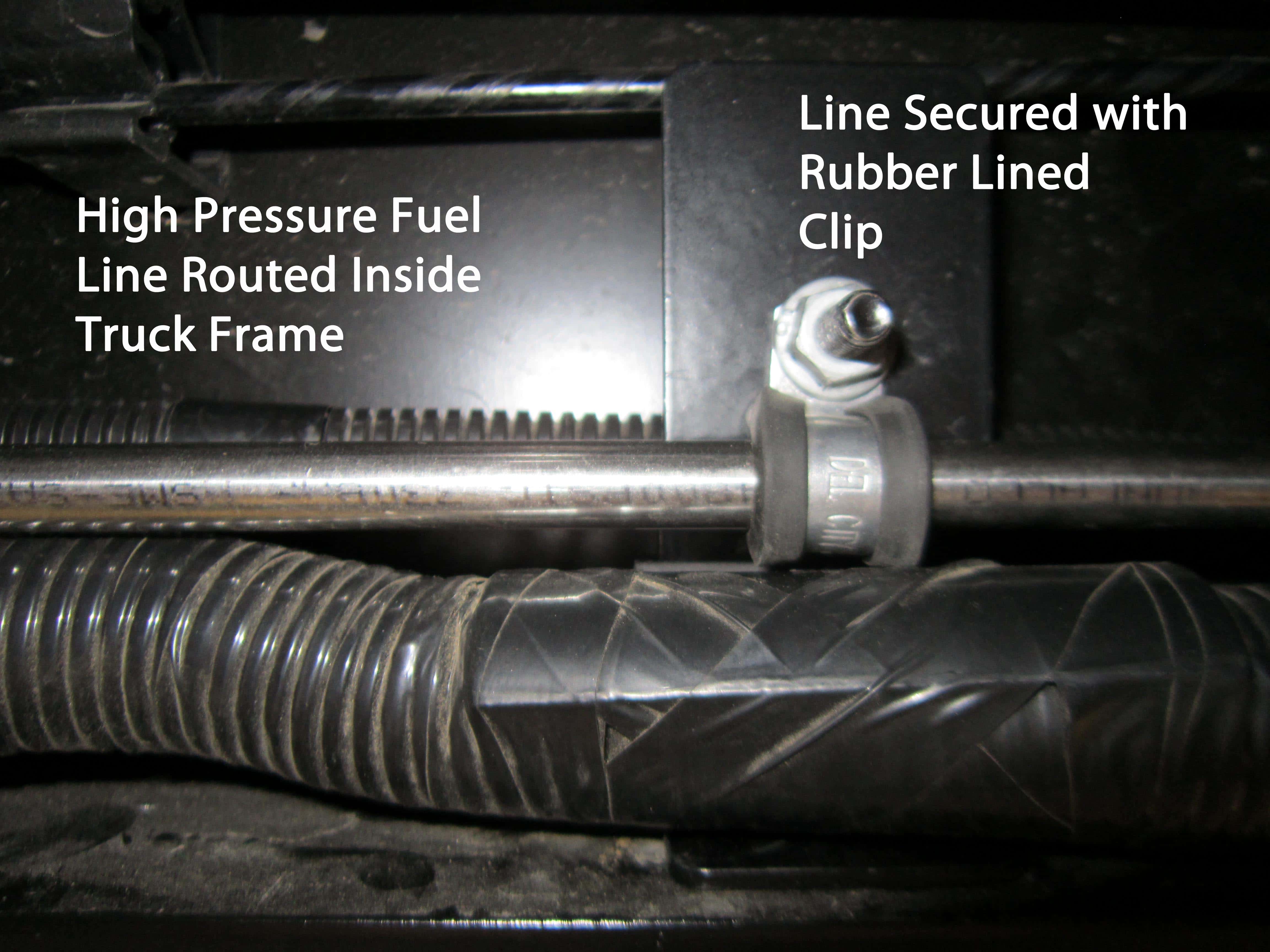

Choose a protected area: Fuel lines should always be located in a protected area of the vehicle. Always package fuel lines inside the frame on ‘body on frame’ vehicles, or in areas such as the inner side of the structural floor pan beam on ‘unitized’ vehicles. This will help protect the lines from being damaged by splash, flying stones or other road debris.

The one exception to this rule is the line connected to the fill receptacle. The receptacle needs to be mounted in an accessible location, which is typically near or behind the existing fuel fill door of the vehicle.

Maintain proper clearances: Fuel lines should always be routed away from heat sources and away from components that have relative movement during vehicle operation. In the case of heat sources, such as the exhaust system or the catalytic converter, OEMs typically require a minimum of between eight and 12 inches of clearance between the heat source and the fuel lines. If a heat shield can be placed between them, the clearance can be reduced.

With moving components, such as the suspension, intermediate steering shaft or the engine/transmission, typical minimum fuel line clearances are two to three inches from the travel envelopes of the moving components.Â

Create a friendly environment for the fuel lines: Always route fuel lines away from sharp edges or protruding objects that may be present in the vehicle underbody area. These sharp edges or protruding objects could puncture or otherwise damage the fuel lines during a collision, or if they should move during vehicle operation, they could rub against the CNG fuel lines and cause abrasion damage.

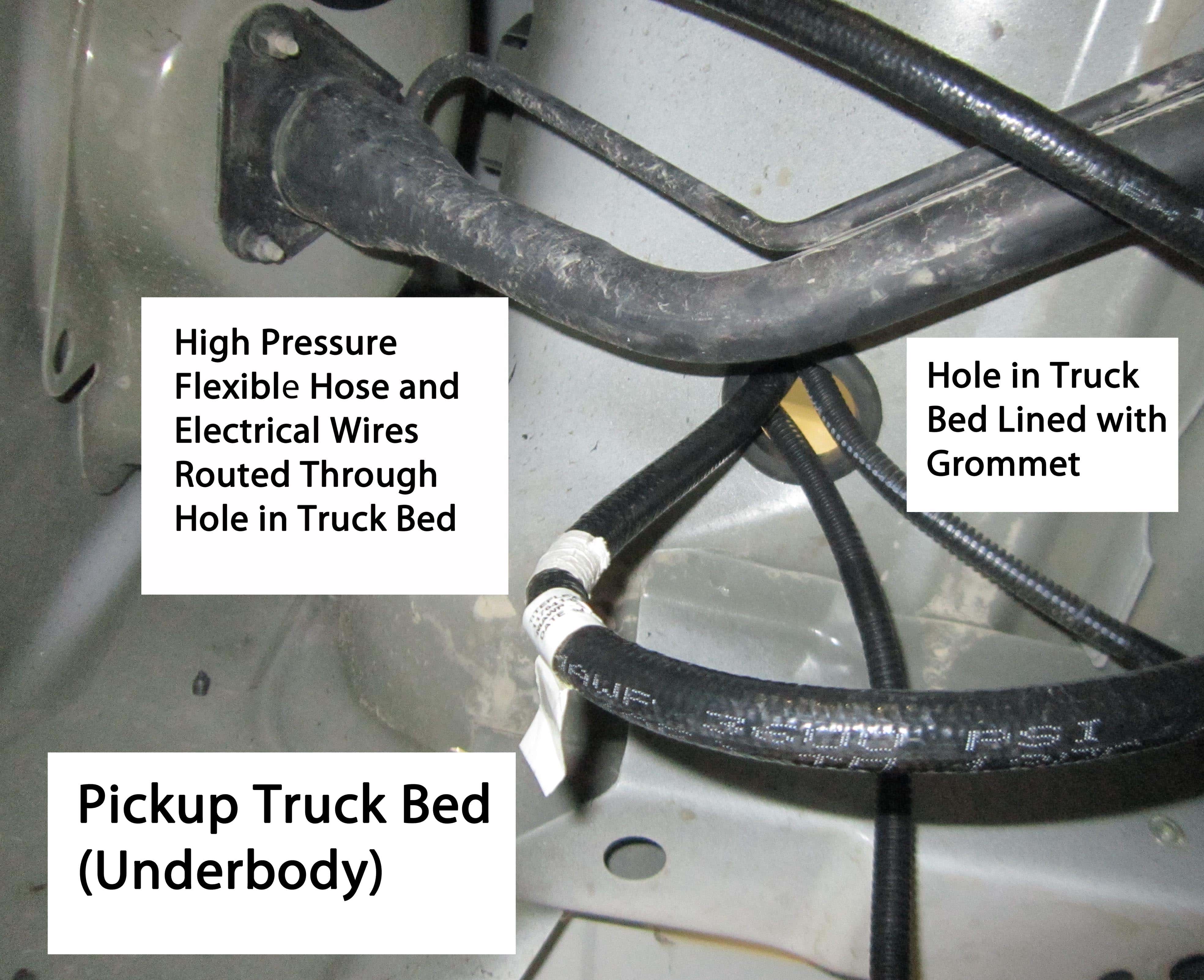

Minimize routing through sheet metal: Whenever possible, the fuel lines should pass under the body sheet metal rather than through it. In those situations where fuel lines absolutely must be routed through sheet metal, such as through the bottom of the truck bed, bulkhead fittings or elastomeric grommets should be used to protect the CNG fuel lines against damage.

Rigid tubing vs. flexible hose

In the battle between rigid tubing and flexible hose, which one wins? First off, flexible hose has two disadvantages: higher cost and permeation of fuel. Flexible hose costs roughly three times as much as stainless steel tubing, and when under pressure, flexible hose permeates fuel into the atmosphere.

Despite these disadvantages, a number of low-volume aftermarket CNG converters prefer to use flexible hose exclusively because it is easier to install and package on vehicles than rigid tubing. Because their CNG conversions are relatively low in volume, they are willing to absorb the material cost penalty.

Currently, aftermarket converters are not required to meet evaporative emissions standards, whereas OEM vehicle manufacturers must meet such requirements. Consequently, permeation is not an issue.

Automotive OEMs such as GM, Ford and Chrysler traditionally use rigid tubing for the majority of their fuel lines and use flexible hose only when absolutely necessary. OEMs typically use flexible hose in those areas where crash compliance or moving component compliance is required, and to make that ‘jump’ from the vehicle underbody to the engine compartment to allow for engine roll. Occasionally, flexible hoses are also used as assembly aids.

Because the OEMs typically build vehicles in extremely high volumes, they choose to avoid the higher material costs of flexible hoses in favor of the lower-cost rigid tubing. OEMs are required to meet evaporative emissions standards, and hence minimize use of flexible hoses due to the permeation concern.

In any case, fuel lines must be securely fastened so that they cannot come loose during vehicle operation or as the result of a collision. Fuel lines should be clipped, usually to the frame or sheet metal, with a typical clip spacing of between 18 and 24 inches.

If the clips to be used are metal, they should have plastic or rubber insulators. If clips are attached with a threaded fastener (e.g., a self-tapping screw), be aware of what is in your fastener's path. Avoid screwing into a wire harness, a brake line or other critical component. Do not attach other components, such as wire harnesses, to the CNG fuel lines, and do not attach the CNG fuel lines to the OEM gasoline or diesel fuel lines or other critical components.

Also, when routing and fastening fuel lines, avoid creating pockets that could trap water, salt or other contamination that could cause premature corrosion concerns.

Mike Spears is the product development manager at AFV LLC, a subsidiary of SSP that focuses on providing tube and hose assemblies for natural gas vehicle fuel systems. Spears spent his career with Ford Motor Co. until retiring in 2007. From 1998 to 2003, he was the pressure vessel and fuel line expert for Ford's alternative fuel vehicle department, and he was a member of the NGV 2 and NGV 3.1 Technical Working Groups. Spears can be reached at mike.spears@altfuelexpress.com.