With a $1.08 million contract award from the United States Advanced Battery Consortium LLC (USABC) – a collaborative organization of FCA US LLC, Ford Motor Co. and General Motors – a materials engineering research team at Worcester Polytechnic Institute (WPI) in Massachusetts will extend the development of its process to recycle spent lithium-ion (Li-ion) batteries and produce new cathode materials that are increasingly being adopted by automotive battery makers to reduce cost and increase energy density.

Building on a successful phase one (completed earlier this year), the contract award, which includes a 50% cost share, funds a 24-month phase two project.

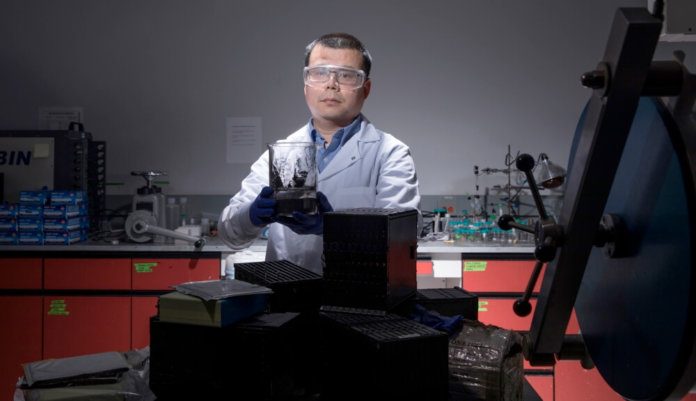

The WPI team, led by Yan Wang, William Smith Foundation dean’s associate professor of mechanical engineering, has developed a patented closed-loop recycling process in which the batteries are first shredded. After the shredded materials are separated, the cathode powders are dissolved. By adjusting the chemistry of the solution, new materials in the desired ratios can be precipitated out as precursor and used to make cathode materials for new batteries, explains WPI. Other materials recovered from the shredded batteries, including steel, graphite and plastics, can also be recycled, thus benefiting the environment and improving the overall business model.

As part of the phase one, Wang took the process developed in his lab and proved that it can be scaled up to produce cathode materials that are equal in quality to those available commercially and that those recovered materials can be used to make new vehicle batteries that are comparable to units sold by original equipment manufacturers (OEMs) for use in hybrid and electric vehicles.

At the time the research was completed, the WPI recycling process was shown to be effective in recycling batteries that contain the most commonly used cathode materials to produce new cathode powders. But over the past few years, battery makers and car manufacturers have increasingly been moving toward higher nickel cathode formulations in efforts to reduce the quantity of cobalt contained in the cathode powders, says WPI.

The switch to nickel is resulting in better batteries, as nickel-rich cathodes offer higher energy density (a greater ability to store energy) than cobalt-rich cathodes. But, according to Wang, producing nickel-rich cathodes is a more demanding process that requires additional steps not required for cobalt-rich cathodes.

“In the first phase of our USABC project, we gained fundamental knowledge about how to control our process to produce cathode particles with the desired properties,” says Wang. “While the conditions for forming cathode powders will be different with the high-nickel materials, our process is quite flexible, and I believe it can be adapted to the new formulations.”

As in the original USABC-funded project, the work of making and testing new automotive batteries using the high-nickel cathode powders produced by Wang’s team will be subcontracted to A123 Systems and Battery Resourcers, a company that has licensed WPI’s patented Li-ion battery recycling process.

“WPI is the first and only university to be granted an award from the USABC,” Wang adds. “The consortium’s funding usually goes to industry because the focus is always on innovations that can be commercialized and used by the automotive industry. The USABC and the OEMs have been very helpful to us as we have worked to perfect and commercialize our process because they see this as a viable solution to their growing end-of-life battery problem.”